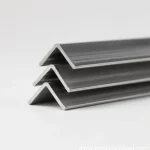

316 stainless steel square tube represents one of the most versatile and widely used structural materials in modern industry. This article explores its properties, applications, and significance across various sectors.

Material Composition and Properties:

316 stainless steel contains approximately 16-18% chromium, 10-14% nickel, and 2-3% molybdenum. The addition of molybdenum significantly enhances corrosion resistance, particularly against chlorides and other harsh chemicals. The square tube format provides excellent structural integrity while maintaining relatively light weight.

Key Characteristics:

Superior corrosion resistance

High strength-to-weight ratio

Excellent weldability

Temperature resistance (-254°C to 800°C)

Non-magnetic properties

Aesthetic appearance

Easy maintenance

Industrial Applications:

Marine Industry:

Boat railings and frameworks

Offshore platform components

Marine equipment manufacturing

Dock construction elements

Chemical Processing:

Transport piping systems

Storage tank construction

Process equipment fabrication

Chemical reactor components

Architecture and Construction:

Structural support elements

Decorative installations

Handrails and balustrades

Building facades

Food and Beverage Industry:

Processing equipment

Storage tanks

Transport systems

Sanitary fittings

Manufacturing Process:

The production of 316 stainless steel square tube involves several steps:

Hot rolling of steel billets

Formation into square shapes

Welding of seams

Heat treatment

Surface finishing

Quality inspection

Market Trends:

The global demand for 316 stainless steel square tube continues to grow, driven by:

Increasing infrastructure development

Growing marine industry requirements

Expansion of food processing facilities

Rising chemical industry demands

Installation and Maintenance:

Installation requires proper handling and specific welding techniques. Regular maintenance typically involves:

Periodic cleaning

Inspection for damage

Corrosion monitoring

Surface treatment when necessary

Economic Considerations:

While initial costs may be higher than alternative materials, 316 stainless steel square tube offers:

Long-term cost effectiveness

Reduced maintenance requirements

Extended service life

High salvage value

Environmental Impact:

316 stainless steel is environmentally friendly because:

It’s 100% recyclable

Has long service life

Requires minimal coating or treatment

Reduces waste through durability

Safety Considerations:

When working with 316 stainless steel square tube:

Use appropriate handling equipment

Follow proper welding procedures

Maintain safe storage practices

Implement correct cutting techniques

Future Prospects:

The future of 316 stainless steel square tube looks promising with:

Emerging applications in renewable energy

Advanced manufacturing techniques

New surface treatment technologies

Innovative joining methods

Quality Standards:

Products must meet various international standards:

ASTM specifications

ISO requirements

Industry-specific certifications

Regional building codes

Selection Criteria:

When choosing 316 stainless steel square tube, consider:

Load-bearing requirements

Environmental conditions

Budget constraints

Installation methods

Aesthetic requirements

This material continues to be a cornerstone in modern engineering and construction, offering an optimal balance of strength, durability, and corrosion resistance. Its versatility and reliability ensure its position as a preferred choice for demanding applications across multiple industries.

Leave a Reply